Hose Reels: The Unsung Heroes Powering Efficiency Across Industries

From Factories to Farms, How Smart Reeling Systems Are Reshaping Workflows

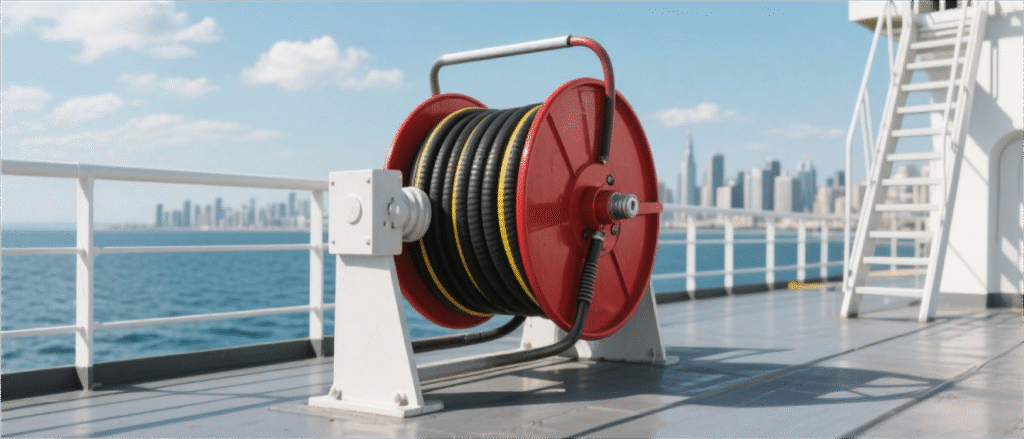

1. Core Functions: Beyond Basic Cable Management

Hose reels (or cable reels) are engineered to store, deploy, and retract hoses, cables, or tubing efficiently. Their core value lies in:

- Safety Enhancement: Preventing tripping hazards by eliminating tangled cables in factories .

- Operational Efficiency: Reducing setup time by 70% for tasks like equipment refueling or irrigation deployment .

- Resource Protection: Extending hose/cable lifespan by 200% by minimizing abrasion and kinking .

2. Industrial Applications Driving Innovation

① Manufacturing & Automation

- Robotic Workcells: Steel-core reels supply hydraulic/pneumatic power to assembly-line robots while withstanding continuous motion stress.

- Chemical Transfer: Explosion-proof reels (ExdⅡBT4-rated) enable safe transfer of volatile fluids, featuring Teflon seals to contain leaks .

② Energy & Utilities

- Renewable Installations: Corrosion-resistant reels deploy coolant lines in wind turbines and solar farms, operating in salt-spray environments for 10+ years.

- Emergency Response: Portable reels with quick-connect fittings allow rapid deployment of fuel/water hoses during disasters .

③ Agriculture 4.0

- Smart Irrigation: Auto-retracting reels integrate soil moisture sensors, optimizing water usage by 35% while reducing manual labor .

- Pesticide Management: Chemical-resistant polymer reels prevent degradation during precision crop spraying.

④ Healthcare & Biotechnology

- Medical Gas Delivery: FDA-compliant reels with antimicrobial coatings distribute oxygen in ICUs, ensuring sterile pathways .

- Lab Fluid Handling: Sanitary-grade reels transfer bioreactor media without contamination risk.

3. Cutting-Edge Use Cases Redefining Possibilities

- Electric Vehicle (EV) Charging: Retractable cable systems in parking structures enable clutter-free high-voltage charging (up to 350kW) .

- Data Center Cooling: Overhead refrigerant line reels maintain optimal server temperatures while simplifying maintenance access.

- Urban Vertical Farming: Space-saving reel systems automate nutrient delivery in hydroponic towers, boosting yield density by 50% .

4. Technology Evolution: From Manual to Autonomous

Modern reels leverage breakthroughs to solve historic pain points:

| Technology | Traditional Reels | Smart Reels |

|---|---|---|

| Drive Mechanism | Hand-cranked | Maglev motor (zero friction) |

| Control System | Manual tension adjustment | IoT sensors + AI torque control |

| Durability | 500–1,000 cycles | 100,000+ cycles (self-lubricating) |

| Environmental Adaptability | Prone to corrosion | Nano-ceramic coatings + UV resistance |

Example: Mining rescue teams now use AI-coordinated reels that auto-adjust retraction force based on hose sludge buildup, cutting retrieval time by 60% during floods .

5. Future Frontiers: Sustainability & Autonomy

- Self-Powering Reels: Integrated solar薄膜 (thin-film) panels generate energy during deployment, enabling off-grid operation .

- Predictive Maintenance: Vibration sensors detect bearing wear 3 weeks before failure, slashing downtime costs by 45%.

- Material Revolution: Mycelium-reinforced biopolymers replace 60% of steel components, reducing carbon footprint per unit by 8.2 tons .

Conclusion: The Strategic Value of Intelligent Reeling

Hose reels have evolved from passive accessories to mission-critical systems that:

- Save Lives by enabling rapid response in emergencies,

- Protect Profits through reduced resource waste and extended asset life,

- Drive Sustainability via energy-efficient operations and eco-materials.

For industries seeking operational resilience, investing in smart reel technology isn’t optional—it’s the backbone of future-ready infrastructure.